Art Bounty

Discover the vibrant world of art and creativity.

Spray Control Secrets That Pros Don't Want You to Know

Unlock the secrets of spray control that experts keep hidden—transform your technique and achieve flawless results every time!

The Ultimate Guide to Mastering Spray Control: Tips from the Experts

Mastering spray control is essential for achieving optimal results, whether you are applying pesticides, fertilizers, or paint. According to industry experts, one of the first steps in perfecting your technique is to understand the various factors that influence spray distribution, such as nozzle selection, pressure settings, and environmental conditions. For instance, choosing the right nozzle can drastically alter the droplet size and flow rate, directly affecting coverage and effectiveness. Make sure to consult manufacturer guidelines and consider conducting test sprays to find the ideal setup for your specific application.

Additionally, maintaining consistent spray control is critical for reducing waste and ensuring safety. Experts recommend following these top tips:

- Calibrate your equipment regularly to ensure accurate application rates.

- Monitor wind speed and direction to minimize drift.

- Keep a steady pace and distance from the target surface to maintain uniform coverage.

- Invest in technology such as GPS and flow meters for enhanced precision.

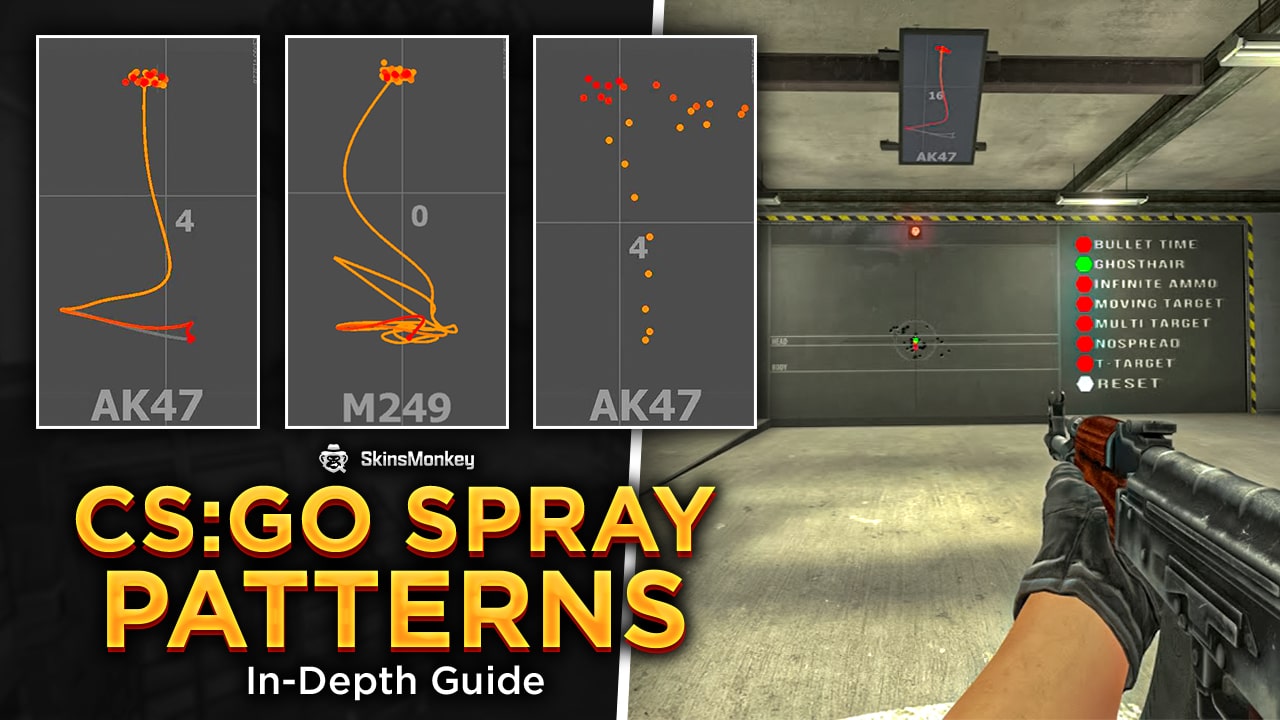

Counter-Strike is a team-based first-person shooter that has become a staple in the esports community. Players can engage in intense matches while strategizing with their teammates. To enhance your experience, it’s important to know how to check trade history steam to track your in-game items and trades.

5 Common Mistakes in Spray Control and How to Avoid Them

5 Common Mistakes in Spray Control can significantly impact the effectiveness of your application. One of the most prevalent errors is incorrect nozzle selection. Using the wrong nozzle type or size can lead to uneven coverage and inefficient chemical usage. To avoid this mistake, always consult the manufacturer’s guidelines and consider the specific requirements of your spray operation. Additionally, calibrating your equipment before use is crucial, as improper calibration can result in either over-application or under-application of materials.

Another common mistake is neglecting environmental conditions. Factors such as wind speed, temperature, and humidity can significantly affect spray drift and evaporation rates. To mitigate this issue, schedule your spraying activities during optimal weather conditions, ideally on calm, cool days. Lastly, failing to maintain equipment leads to reduced performance and increased risks of malfunction. Regular inspections and maintenance of your spray equipment can ensure that it operates efficiently and effectively, helping you to avoid costly errors and improve overall application results.

What Every Beginner Needs to Know About Spray Control Techniques

Spray control techniques are essential for beginners looking to optimize their spraying processes, whether in agriculture, painting, or other applications. Understanding these techniques helps ensure an even application of materials, minimizes waste, and reduces harmful overspray. The first step for beginners is to recognize the different types of spray systems available, such as air spray, airless spray, and electrostatic spray. Each type has its own advantages and is suitable for specific tasks, so it is crucial to choose the right one based on your needs.

Moreover, mastering spray control techniques involves learning how to adjust the spray pattern, pressure, and distance from the target surface. Beginners should consider the following key factors to achieve optimal results:

- Tip Size: Selecting the appropriate tip size is essential for controlling flow rate and droplet size.

- Pressure Settings: Adjusting the air or hydraulic pressure affects the spray atomization and coverage.

- Distance and Angle: Maintaining the correct distance and angle from the surface prevents uneven application.

By focusing on these aspects, beginners can develop effective spray control techniques that enhance their overall project quality.